top of page

THE AVI35 HEAT EXCHANGER

The Avi35 is a 1500 CFM cross flow plate exchanger that proposes an efficient and affordable solution to improve barn winter ventilation

The exchanger can be wired parallel to a second AVI35 to exchange 3000 CFM trough two units on the same circuit.

0° C

20° C

11° C

1500 CFM

3200 RPM

AUTOMATIC WASHING CYCLES IMPROVES HEAT TRANSFER EFFICIENCY

INTELLIGENT DEFROST CYCLES PREVENTS ICE BUILD UP IN THE CORE

UP TO 65 % SENSIBLE HEAT RECOVERY EFFICIENCY AT 600 RPM

HOW DOES IT WORK ?

Two variable ECI ventilators forces two air flows to travel through independent pathways inside the exchange core.

The core consists of hundreds of small tubes that make up the air pathways. The warm moist air pathway is vertical and the cool fresh air pathway is horizontal. The key is that both tube pathway share a common wall.

As warm air flows along the exterior side of the tube, it heats up the latter tube wall. As fresh air flows along the interior side of the tube, it captures the heat stored in the wall. There you have heat exchange across the common wall

Heat transfer crossing the common wall

KEY FEATURES

Two ECI 14 inch variable speed ventilators drive the exchanger. 3200 maximum RPM

The ECI ventilators are controlled with 0-10v and have MODBUS communication capabilities

The exchanger consumes as little as 50 watts at minimum speed

ECI ventilators consume very low power at low speeds

The Avi35 cartridges are cross flow polymer plate exchanger cores

The core total surface area for heat exchange is approximately 35 square meters

Can be pressure washed and soaked in soap or disinfectant

The rinsing assembly comes standard with all exchangers.

Six nozzles rinse the core several times per day to remove the accumulated dust

By removing the dust, the exchange plates remain thin and heat exchange and air flow is maximized

The Avi35 is a study unit designed to have easy access to the cartridges from inside the building though a large solid stainless steal door

A flange moulded in the polypropylene housing facilitate the wall mount installation

The Avi35 rough stud opening is 28.75 inch wide and 66.5 inches high

Each heat exchanger will greatly reduce fossil fuel usage, one can expect 50 % consumption reduction in broiler production

On average the Avi35 reduces farm greenhouse gases ( GHG) emission by 3 tons per year per unit in broiler production

Contact us to know more about GHG subsidy programs in your province

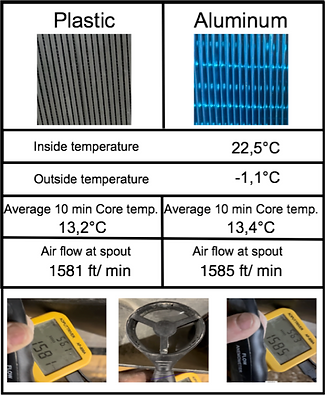

WHAT IS THE IDEAL CORE MATERIAL ?

In an heat exchanger, total heat transfer must account for the sum of all heat transfer resistance in the system.

When the tube wall of the exchanger is very thin and the substance to transfer heat has a very low convection heat transfer coefficient, like air, the material making the wall is irrelevant. Aluminum is equivalent to plastic.

Avi-Air believes the longterm resilience of the core material and its ease of maintenance is more crucial than the conductivity properties of the material.

Depending on the application Avi-Air offers both cartridge types.

bottom of page